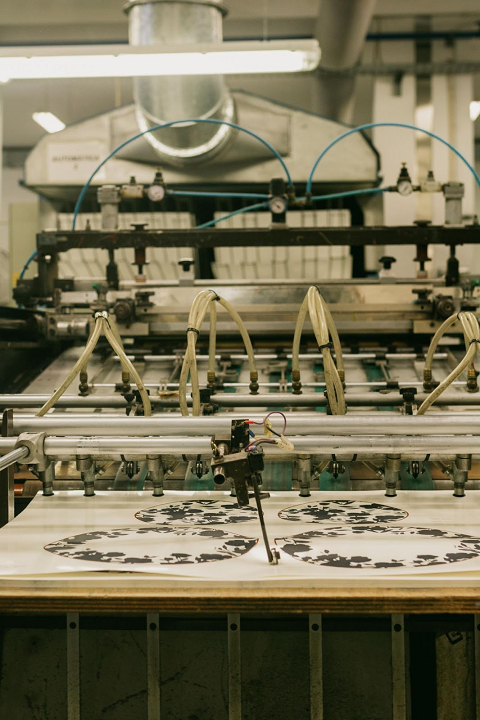

DTF printers are best for transforming the textile industry by using the latest technology to upgrade production speed, quality, durability, and versatility. They are meant to provide the printings in the fabric a new life. Therefore, whether it is a small or a big business firm, investing in a DTF printer is always recommended.

However, with all its benefits, DTF printers also have issues that need a little care. The maintenance will further extend the life of your DTF machine printers. This blog provides some tips and tricks on maintaining your digital printer for fabric to avoid any kind of interruption and disruption in the work process.

Tips for Regular Maintenance

The cleaning process is divided according to the months. Some cleaning has to be done on a regular basis, but some can be done in intervals.

Regular Maintenance

- Cleaning the Print Head: The print head is an important part of the DTF printers that comes with the issue of building up ink in the nozzles leading to clogs. However, this problem can be solved by regularly cleaning the nozzles and using the automated cleaning feature in the DTF printer.

- Monitoring and Refilling the Ink: The ink level has to be checked weekly, as running out of ink can lead to severe damage to the printers. It is, therefore, important to check the ink level of the DTF printers. You can also use the printer’s software to monitor the ink levels. Using high-quality ink in your DTF printers is also recommended to improve optimal performance.

Weekly Maintenance of the Machine

- Cleaning of the Capping Station: The capping station can be seen near the print head, and it is needed to keep the print head, preventing clogs and retaining moisture. The capping station has to be kept clean by whipping it down using a lint-free cloth. You must also check the debris that can block the station and clean it accordingly.

- Monitoring the Roller: Dirty rollers generally lead to misfeeds, and to avoid such circumstances, clean the rollers and replace them when necessary.

Monthly Check-up

- Updating the Firmware and Software: Keeping the DTF printers updated with the latest technology is important to improve their efficiency and performance. Instructions on the machine must be followed for any kind of updates.

- Deep Cleaning Process: Daily involvement is not required in deep cleaning. In this regard, the manufacturer’s manual is important to know how to disassemble and clean the parts to increase their performance rate. Usage of proper cleaning materials is required here to avoid any kind of damage.

Summing Up

DTF Printers are essential for elevating your textile business and enhancing its performance. However, the problems that can reduce the efficiency of the DTF printers can also be solved with the help of periodic maintenance. Ensure your printer’s smooth operation by following the cleaning process mentioned

. Read also more blog shoutingcafe.com .