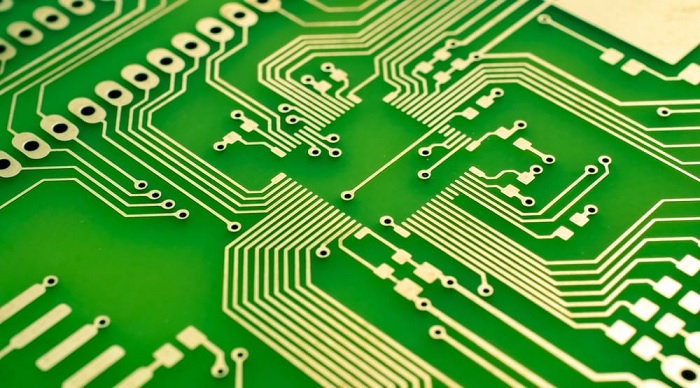

The advance in electronics continuously looks for more functions within smaller, better designs. A major leap is the creation of High-Density Interconnects (HDIs). These are modern printed circuit boards (PCBs) that can accommodate more parts in tinier spaces, making electronic devices more powerful and efficient. This article is about the rising popularity of HDIs made by hardware design company, their benefits, use cases, and future implications.

The emergence of HDIs

Traditional PCBs have worked well for the electronics industry for many years, but when people want smaller and stronger devices, regular boards can’t keep up with this need. HDIs were created to solve these problems by making it possible to design more complex layouts and fit more components into small spaces.

HDIs are known for using microvias, very thin lines, and a high number of connection pads. Unlike regular PCBs that usually have bigger vias and broader traces, HDIs use micro vias—tiny holes less than 150 microns wide—to link different layers on the board. This allows designers to make more detailed and smaller layouts, which greatly improves how the PCB works and performs.

Advantages of HDIs

Increased component density

One big benefit of HDIs is they can fit more parts into a smaller area. This happens because designers use tiny holes called microvias and very thin lines, letting them put many pieces on the same board space without losing how it works properly. This ability is very important for today’s electronic gadgets, which need to do more and more tasks while staying the same size or even getting smaller.

Talking about smartphones, for example, HDI technology has played a big part in the huge improvements we have seen over the last ten years. Nowadays, smartphones come with high-quality cameras, modern sensors, strong processors and lots of memory space—all put together in thin and stylish designs. This combination is possible because HDIs have high component density. By fitting more parts into a tiny area, HDIs let smartphone makers add these new features without making the phone bigger. This is very important for meeting what consumers want: more powerful smartphones, that do many things at once, but are still easy to carry and simple to use.

Enhanced performance

HDIs give better electrical performance than old-style PCBs. The shorter connections and narrower trace widths lessen signal loss and electromagnetic interference (EMI). This means the signals stay stronger, and data can travel faster. This is especially important for high-frequency uses, like 5G communication and fast computing, where it is crucial to keep the signal quality strong.

Improved reliability

The use of microvias in HDIs lets more components fit on the board and also makes the PCB work better overall. Microvias do not get defects as often as bigger vias and their small size helps lower problems from mechanical stress and heat changes. This makes a stronger and more dependable board, which is very important for uses where mistakes cannot happen, like in medical equipment and space technology.

Design flexibility

HDIs give more freedom in design, allowing engineers to make layouts that are complex and new. Being able to put components closer together and route traces in narrower spaces helps create designs of PCB design board in USA that are both creative and efficient. This flexibility is very useful in making new technologies, like bendable and wearable electronics, where usual PCB designs would not work well.

Applications of HDIs

The versatility and performance benefits of HDIs have caused them to be widely used in many different industries. Here are some important uses:

Consumer electronics

The HDI technology is heavily used by the consumer electronics industry. Devices such as smartphones, tablets, laptops and wearable gadgets utilize HDIs to offer more functionalities in smaller and handier sizes. The increased component density and superior performance of HDIs enable these devices to deliver features like high-resolution screens, cutting-edge sensors and batteries that last longer.

Automotive industry

HDI’s impact is also strongly felt in the car field. Presently, cars are equipped with numerous electronic systems such as advanced driver-assistance systems (ADAS), entertainment and information systems, along with electric powertrains. HDIs allow these complex systems to be accommodated into tinier yet more effective components. This helps the vehicle work better and be more reliable overall.

Medical devices

In medicine, HDIs help make advanced and small medical tools. These include things like health monitors you can wear and devices that go inside your body. HDIs give these important medical gadgets the power and dependability they need for serious uses. The ability to put more functions into smaller devices is very important in this industry, where size and weight are often key things.

Aerospace and defense

The aerospace and defence sectors also gain from the sophisticated features of HDIs. The demand for lightweight, high-efficiency electronics in aeroplanes, satellites, and military equipment makes HDIs a perfect choice. The more dependability and efficiency of HDIs make sure these important systems work well in tough situations.

The future of HDIs

The rise of HDIs is an important step in the growth of electronics, but the path forward is still long. With technology always getting better, people will want electronic devices that are even smaller, stronger, and more efficient than before. Several trends and developments are likely to shape the future of HDIs.

Miniaturization and integration

The movement towards making things smaller and more integrated will keep pushing the progress of HDIs. Improvements in how we make these, like using laser drilling and detailed etching, will allow the creating of even tinier and more intricate HDI designs. Additionally, combining HDIs with other cutting-edge technologies like system-in-package (SiP) and multi-chip modules (MCM) will make them even more powerful.

Conclusion

The increase in High-Density Interconnects (HDIs) is a very important time for the change in electronic gadgets. HDIs make it possible to have more functions in smaller and better-designed sizes, which means they are changing many industries and helping new technologies grow quickly. As more people want smaller but more powerful electronic devices, semiconductor design services for HDIs will become more and more important in how future technology develops. The story of HDIs is just starting, with a lot of room for new ideas and progress ahead.

Also Read:- Proven Techniques that Can Help Increase the Efficiency of Your Trolling Motor